Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

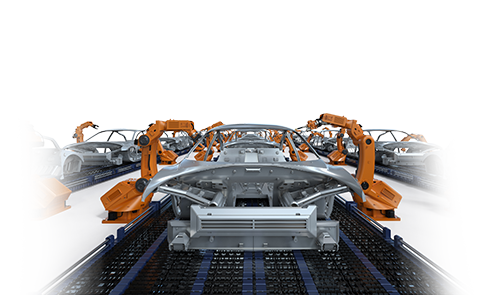

Control System for Assembly Line

Volkswagen, one of the world’s leading automakers, partnered with Altus to leverage high-performance technology to modernize its assembly lines in Brazil.

A precise control system designed to elevate the quality and reliability of the vehicles produced

Reduced downtime through rapid fault detection and identification across the system

The PLC’s seamless communication with field devices enhances decision-making speed for the management team

The system also enhances the centralization of all data related to resource use

Av. Theodomiro Porto da Fonseca, 3101, lote 01 – São Leopoldo/RS – Brasil

CEP 93022-715

© 2024 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.