Our Products

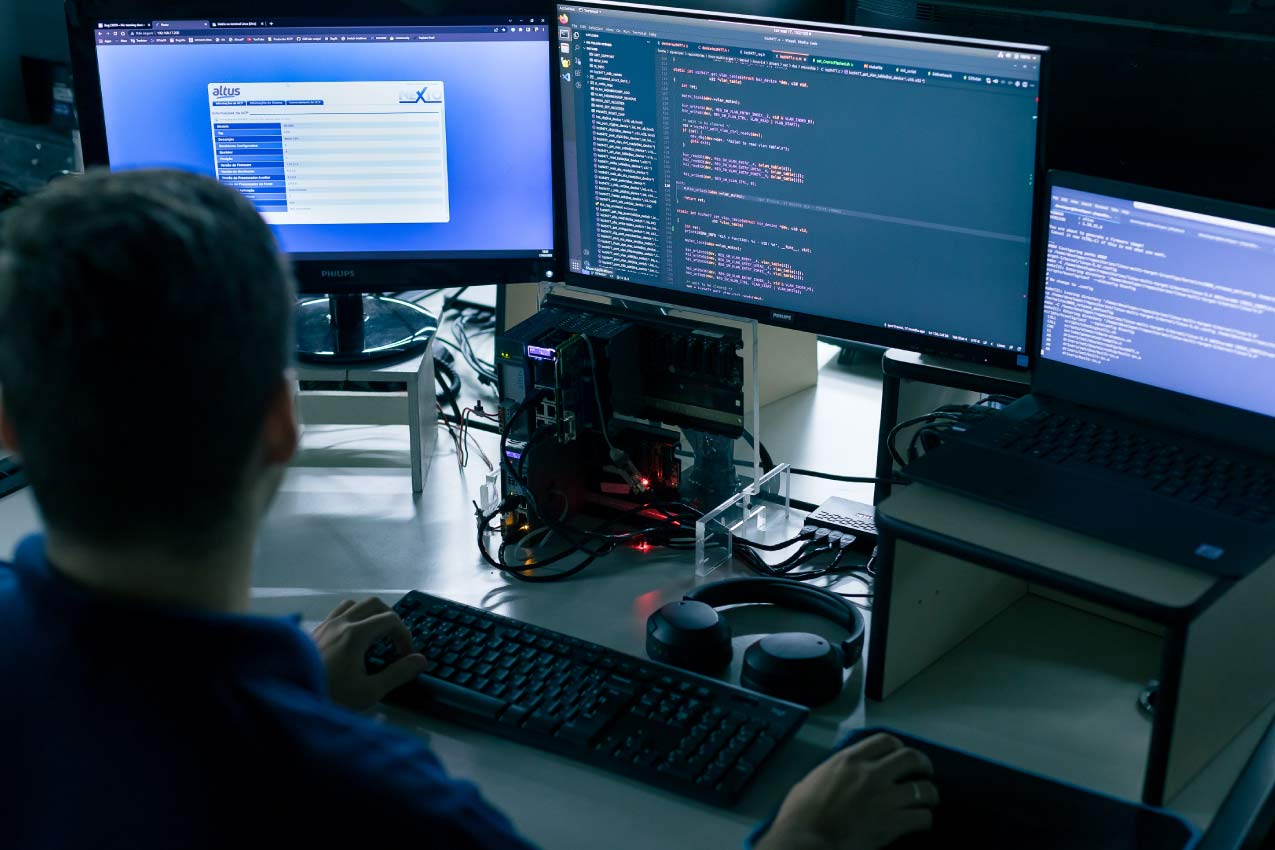

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

Automation of the Carmo, Rio Taquipe, and Almeida/EIA Oil Collection Units

The automation system upgrade is designed to improve data acquisition and process control at the Collection Stations, covering key elements such as waste boxes, production tanks, boilers, separators, treaters, transfer pumps, and, in the case of Almeida, water injection systems.

Centralized and consolidated data to streamline maintenance activities

Effective management planning and operational control across the plant

Automated systems designed to reduce operator staffing per shift

Quick and efficient identification of equipment failures and system issues

The system developed for the Operations Center enables operators to monitor all subsystems and assess the entire process in real time. They can intervene at any moment, taking direct control of various pieces of equipment, notifying stations of any events, and adjusting control set points by interacting with icons and configured interfaces on the screens.

- AL-2003 programmable controllers with Ponto Series - Ethernet Network Interface (AL-3405 module) - Profibus-DP Network Master Interface (AL-3406 module) - Local Human-Machine Interface (Cimrex 90) - Training in programming and maintenance of programmable controllers - Application Development – Ladder and Local HMI software - System testing on platform - Start-up and assisted operation

Av. Theodomiro Porto da Fonseca, 3101, lote 01 – São Leopoldo/RS – Brasil

CEP 93022-715

© 2024 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.