Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

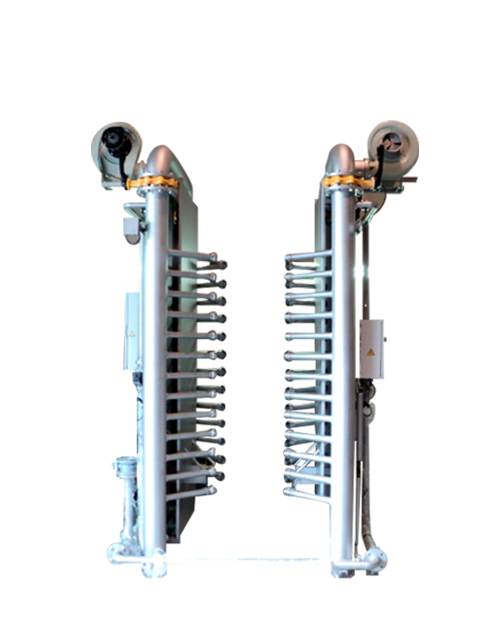

Control System for the Scalding Process

JBS turned to Altus technology to resolve the mechanical failures that were negatively affecting its slaughtering process, leading to significant product losses at the unit.

Real-time monitoring of operational variables through smart sensors, providing up-to-the-minute data

Positioning sensors installed to signal when the carcass is properly aligned with the burners

Standardized heat intensity for each burner involved in the process

The new system significantly reduced product losses caused by burning or incomplete sterilization

To reduce product waste at this stage, an XP325 PLC was installed to synchronize the four burners using clock sensors. This automation ensured consistent heat application on both sides of the carcass. The maintenance team also installed positioning sensors to detect when the carcass is in place, triggering the flames only at the appropriate time.

The new architecture has dramatically reduced product loss due to burning or insufficient sterilization. It has also led to savings in gas consumption, as the flames are activated only when necessary.

To ensure the team could fully leverage the capabilities of the Altus PLCs and other equipment used in the modernization, we provided tailored technical training to the maintenance staff at the client's headquarters.

Carlos Henrique Azambuja, JBS automation technician and developer of the process logic, emphasized the readiness of the Altus technical team in assisting with adjustments and noted how the training programs were pivotal to the project’s success. "A lot of what I know today came from Altus' online certification training," he says.

Jairo de Quadros, the unit’s maintenance and project coordinator, highlights that the independence offered by Altus’ technology platform is one of its key advantages. "The autonomy I get from using Altus PLCs is incredibly reassuring. It gives me confidence in our daily operations. I truly believe in and trust your (Altus) products," Jairo stated.

Av. Theodomiro Porto da Fonseca, 3101, lote 01 – São Leopoldo/RS – Brasil

CEP 93022-715

© 2024 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.