- Segments

- Process Industry

- Chemical Industry

Safety and efficiency for the chemical industry

Maximize your business performance and reduce operational costs, all while ensuring the safety of your workforce

Discover how Altus solutions can deliver high performance for your operations, guaranteeing full operational availability and enhancing the efficiency, safety, and reliability of your production processes.

Ask for a advisory

Do you want to implement your current project with us? We will be happy to advise you!

Projects and solutions for the sector

Ipiranga Loading System

Altus was responsible for the development and implementation of the company's new fuel loading system, applied in several units.

Load System Braskem

Altus technology was applied in the development of Braskem's new fuel loading system, applied in several of the company's units.

YPF Digital Adaptation

Altus technology was used to adapt YPF Química's production processes to the demands of connectivity, safety and high productivity of Industry 4.0.

Pigment Process

Modernization of the electrical panel of the yellow pigment stock of a client specialized in the manufacture and sale of intermediate chemicals.

Our solutions for this industry

Seamless integration from lab to field operations

At Altus, we combine state-of-the-art technology with a highly skilled team of experts to seamlessly integrate systems across your entire production cycle — from delicate laboratory procedures to critical field operations. This integration provides you full control over your operations, optimizing every step of your process for maximum efficiency and top-tier quality.

Our Nexto System programmable controllers are designed to excel in a wide range of environments, whether in stand-alone setups or fully connected systems. Equipped with advanced control and communication features, these controllers are perfect for both laboratory-based applications and distributed field systems, delivering smooth and efficient management throughout your entire production chain.

By partnering with Altus, you’re investing in solutions that optimize your operations, delivering enhanced control, efficiency, and quality at every stage of your business.

Protecting people and boosting productivity in petrochemical operations

The Petrochemical Industry faces unique challenges that demand highly reliable systems to ensure the stability of operational processes and the safety of workers. Our focus is on delivering robust, high-performance solutions specifically tailored to meet the rigorous demands of this critical sector.

Designed to withstand harsh environments, Nexto System programmable controllers ensure the integrity and reliability of your operation, providing peace of mind and efficiency in the dynamic world of petrochemical processes.

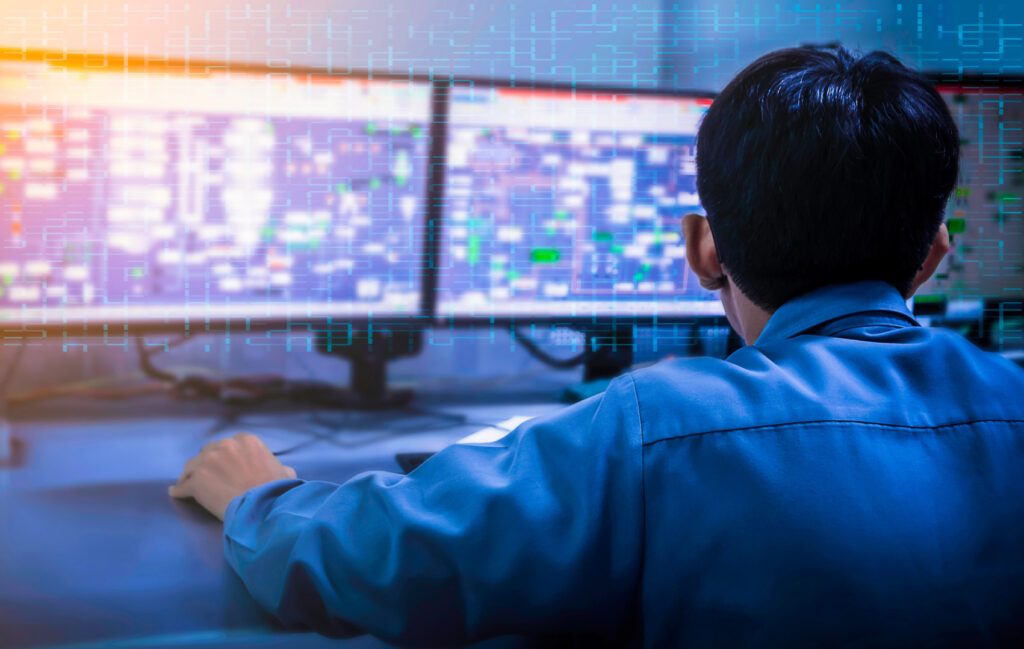

Advanced data collection and processing

Our cutting-edge technology allows for precise data collection, enabling operators to make faster, more informed decisions from the control room or operations center.

With powerful processing capabilities and multiple communication options, Nexto System programmable controllers can function as smart dataloggers. These devices collect critical operational data and communicate seamlessly with the SCADA system overseeing your business.

This advanced functionality empowers operators to make strategic decisions and take actions across distributed units, driving greater efficiency throughout your entire operation.

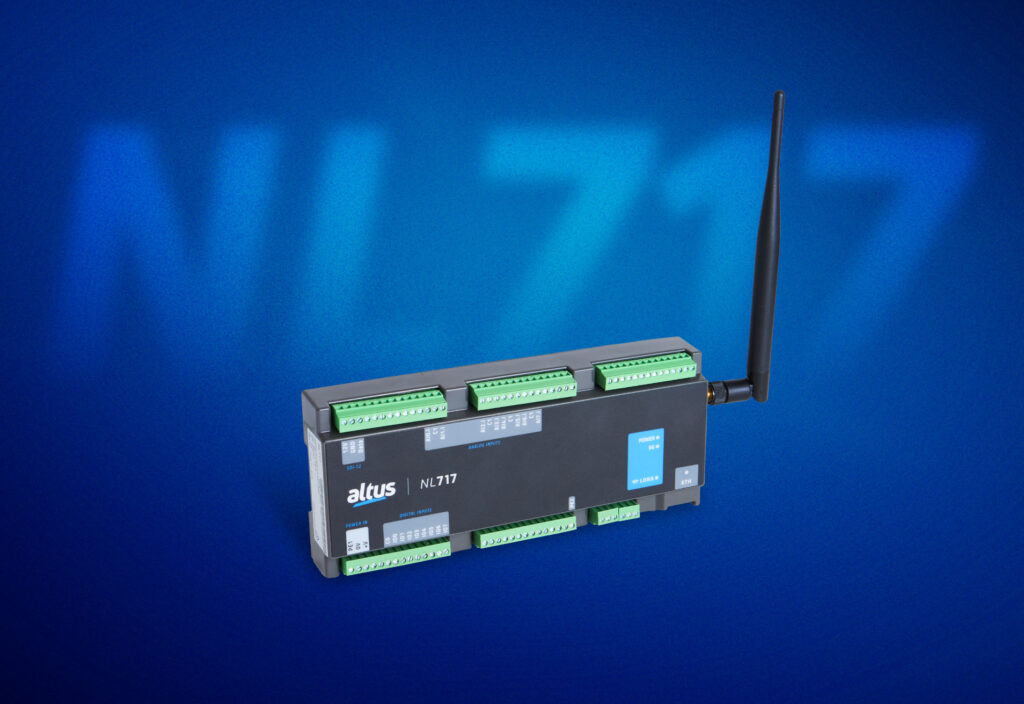

Remote data collection and telemetry with the NL717 datalogger

Altus programmable controllers also enable real-time monitoring of effluent quality, tracking key parameters such as pH, chemical concentration, turbidity, and temperature. These PLCs automatically adjust treatment processes in response to real-time changes in effluent characteristics, ensuring peak performance.

The NL717 is designed to support a broad range of monitoring and telemetry applications, collecting data from sensors through embedded input points or SDI-12 network. This data is stored in the logger’s internal memory and transmitted to control centers via Ethernet or LoRa networks, providing continuous insight into your operations.